APEXPROJECTS is your reliable partner in the world of innovative industrial automation. We provide cutting-edge solutions in the field of programming and integrating industrial robots, helping our partners successfully and efficiently implement projects of various types and complexities. Our engineers specialize in programming and configuring automated systems, including robotic complexes, using various technologies. We work with the most advanced technologies and brands in the industry, ensuring our clients’ needs are met.

Our Project History

Over the years, we have worked on a variety of exciting projects in industrial automation and robotics. In this section, we would like to share some of them to give you a better understanding of the scale and diversity of our work.

Experience

We have experience working with the following systems and technologies:

Industrial Robot Programming – KUKA KRC2, KRC4, VKRC2, VKRC4.

Robot Safety System Commissioning – KUKA SafeOperation, KUKA SafeRangeMonitoring.

handling

stacking

spot welding (Bosch 6000/7000)

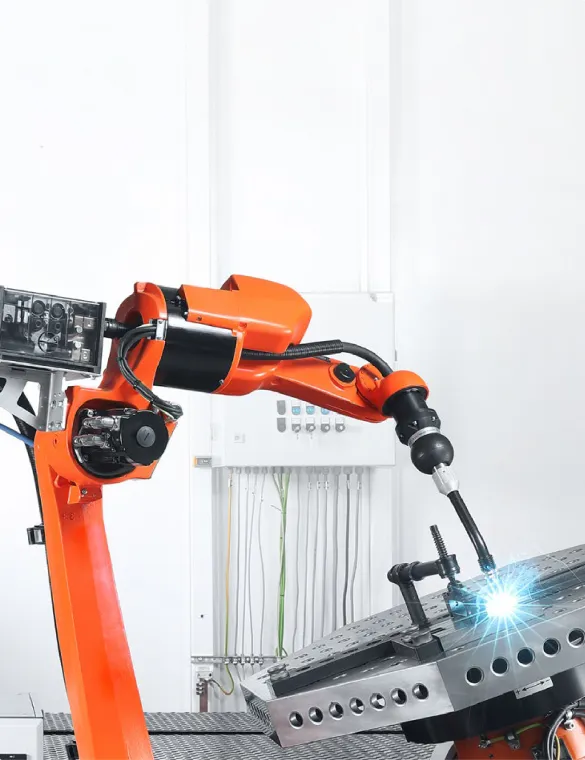

MIG welding

gluing (INTEC, AIK)

best-fit (VMT, Wenglor)

vision systems (SensoPart)

bolt welding (Tucker, Nelson)

riveting (Tox, Henrob, Böllhoff, Eckgold)

screwing (Bosch, Apex, Weber)

Certificates

2023

Weber FDS screwing for experts

2023

TOX pressotechnik riveting

2022

Eckold Servomotoric riveting for experts

2021

Intec gluing system maintenance

2018

KR C4-Safe-Operation: Sicherheitsinbetriebnehmer + Safe-Abnahme eines Systems. Integra 5. Welle

2018

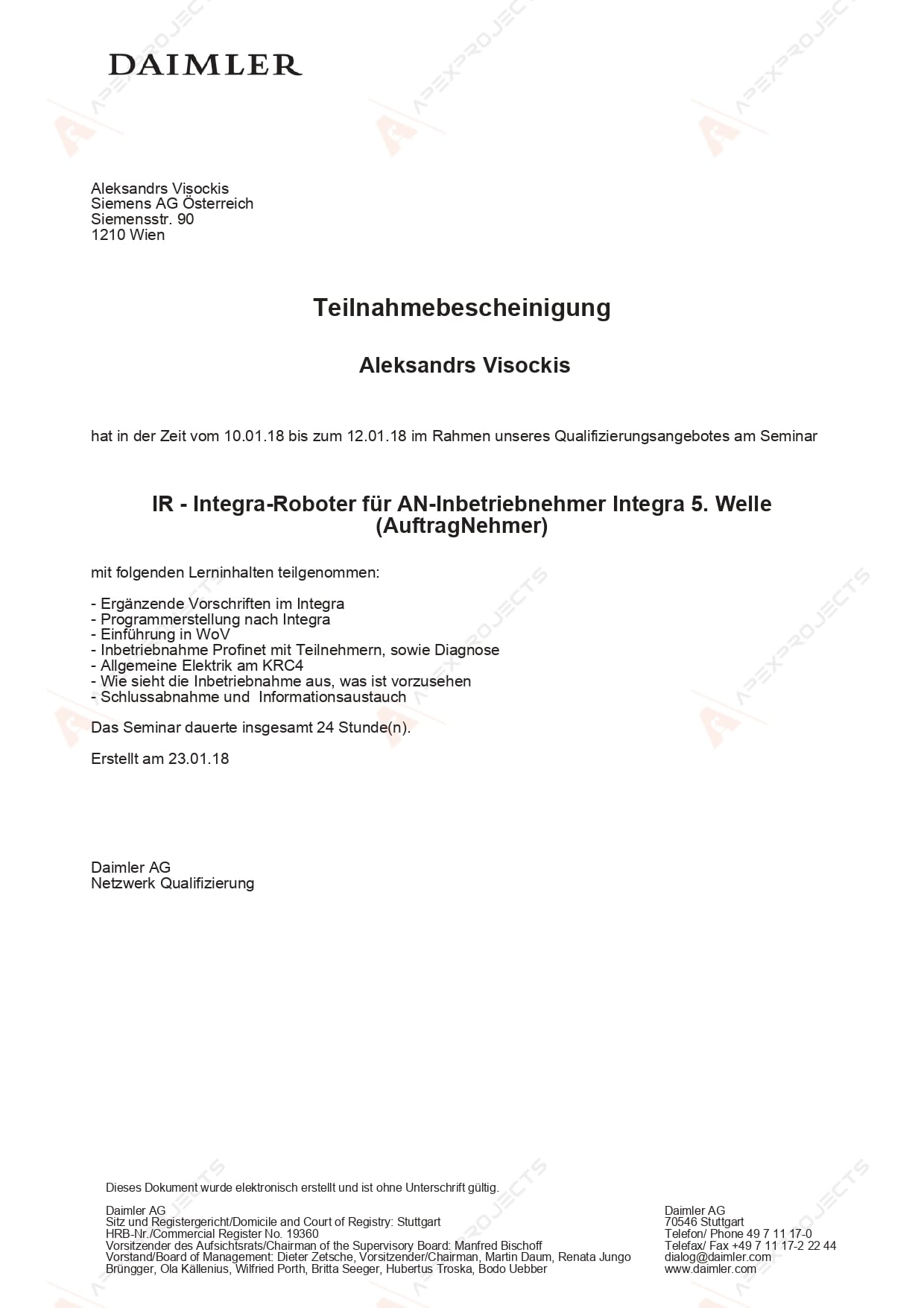

Integra-Roboter für AN-Inbetriebnehmer Integra 5. Welle

2018

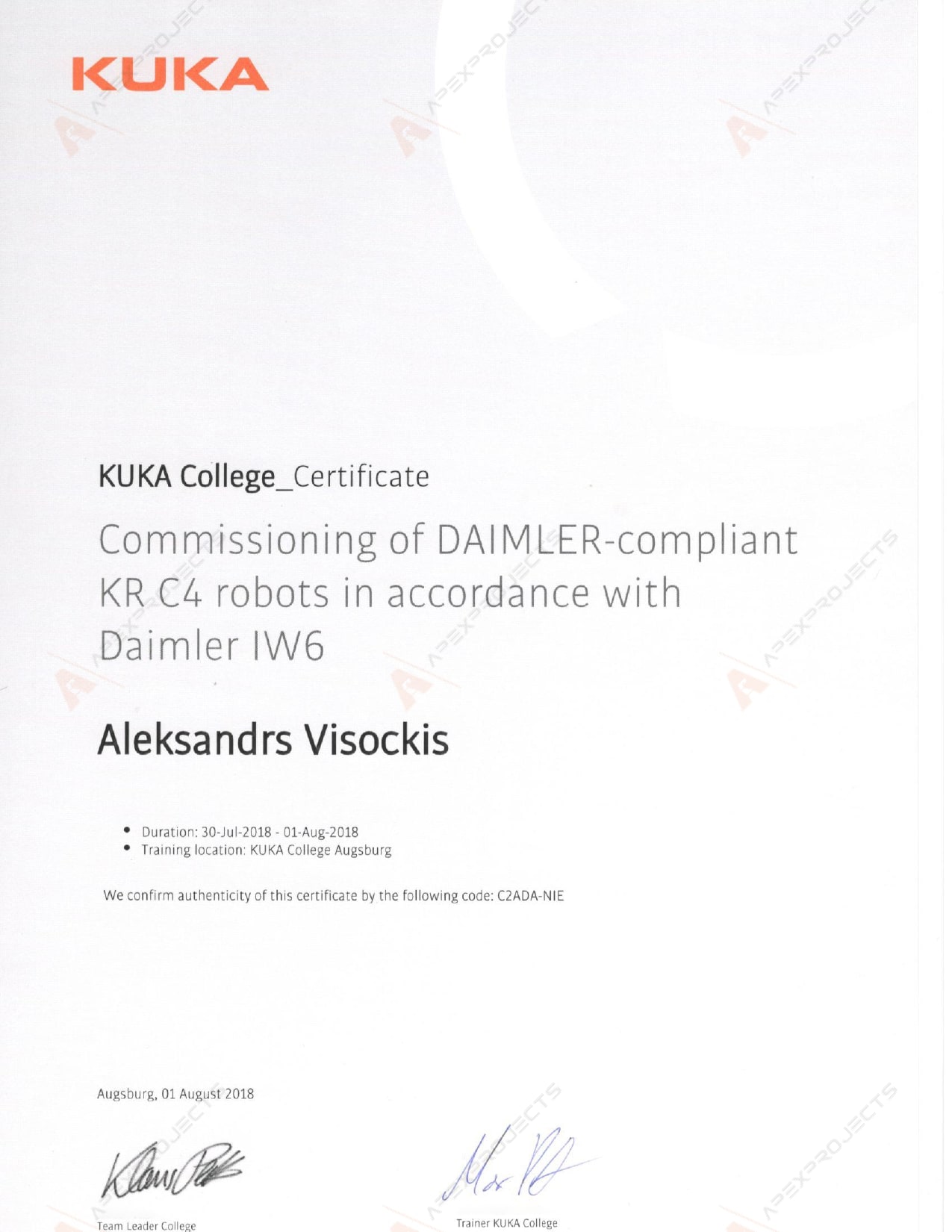

Kuka College Certificate – Commissioning of DAIMLER-compliant KR C4 robots in accordance with Daimler IW6

2013

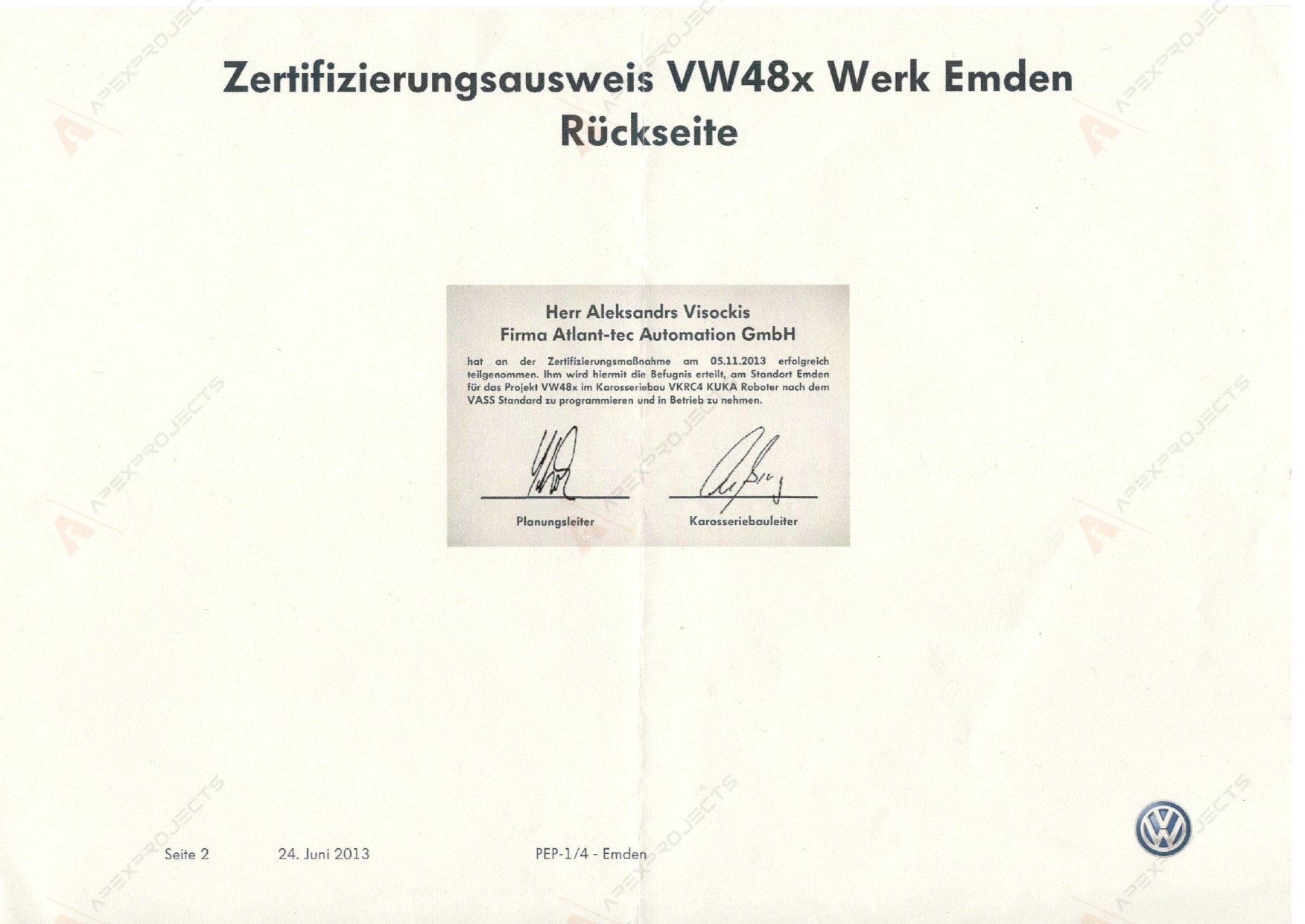

VASS Standart certificate project vw48x in bodyshop vkrc4 KUKA robot

2012

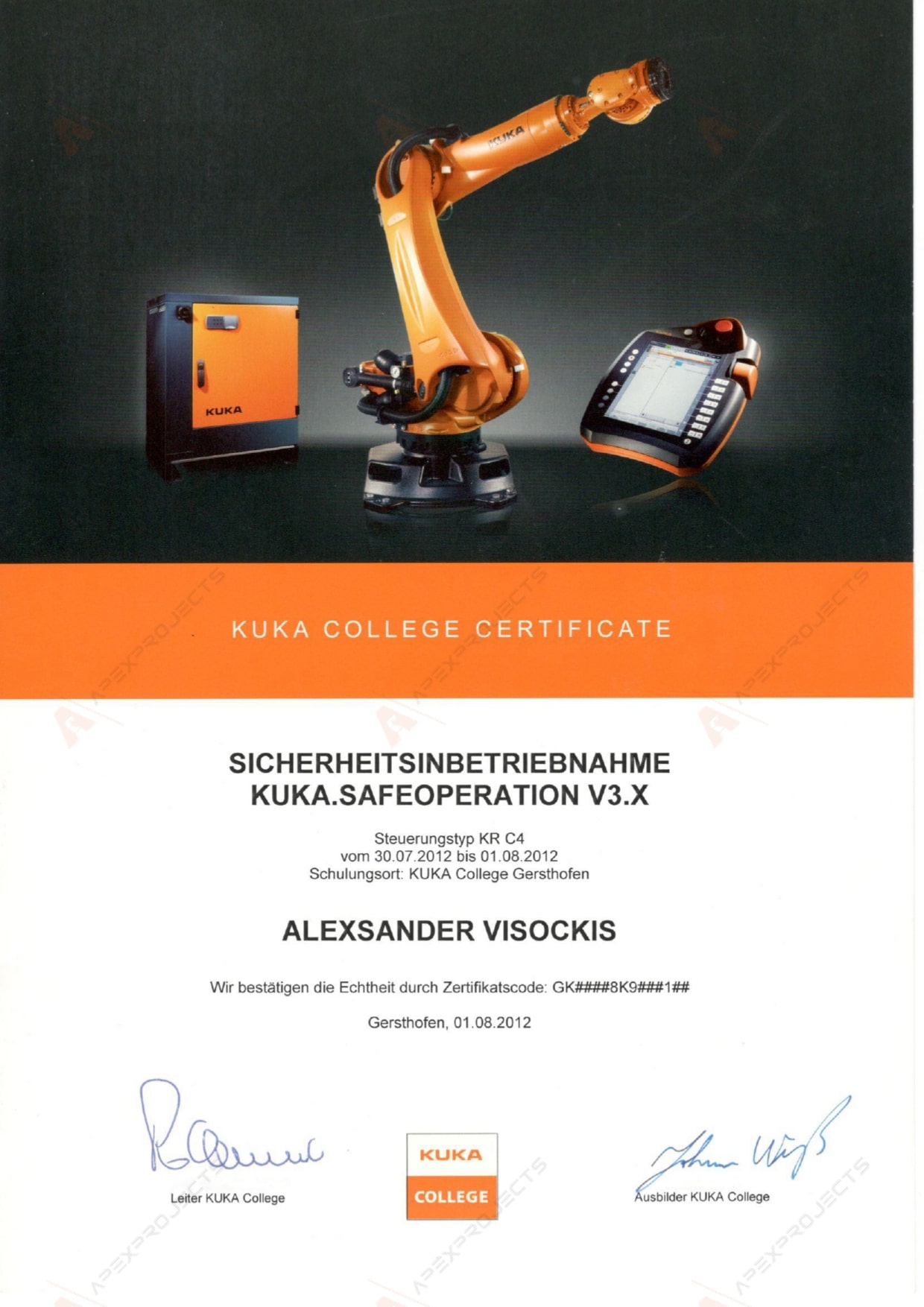

KUKA college certificate KUKA safeoperation v3 x